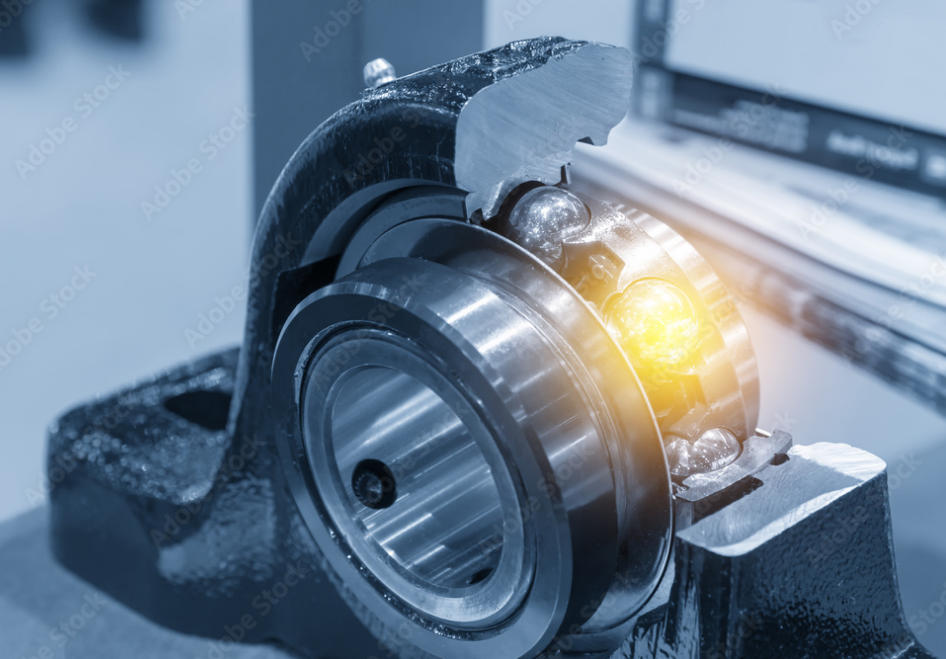

Pillow block bearing

Bearing housing - meaning

Since one bearing can use different bearing seats, and one bearing seat can also use different types of bearings at the same time, there are many varieties of bearing housings. The bearing housing is easy to be included, and many large foreign bearing companies also have their own bearing housing catalogue. However, the same bearing housing models are not exactly the same in different company samples. For different applications of standard bearing housings, housings with different materials such as grey cast iron, ductile iron and cast steel, stainless steel, plastic special housings are available.

Bearing housing - overview

According to the different requirements of the bearing and the bearing housing, the classification of the bearing housing is not completely the same. When using it, it should be carefully checked according to the design.

1 According to the shape of the bearing housing:

1.1 outer spherical bearing, also known as bearing unit (SKF's statement). When there is no bearing, it is called an outer spherical bearing. 1.1.1.1 The outer spherical bearing seat is divided into 200 series according to the series of bearings. 500 series. 300 series. 600 series. XOO series.

1.2 The outer spherical bearing seat is divided into vertical seat (P seat), square seat (F seat), diamond seat (FL seat), round seat (C seat), boss round seat (FC seat), convex according to the shape. Square seat (FS seat), dark hole seat (PA seat), hanging seat (FA seat).

1.3 Integral (ie non-separable) vertical bearing block seat, bearing housing with screw fastening. These vertical housing blocks were originally developed as axle boxes for light rail trucks, but can also be used with conventional vertical housing sets. Non-separate vertical housing blocks are more rigid than split housings and some can withstand heavier loads. The outer spherical bearing housing also belongs to the integral seat.

2 split bearing housing

2.1 Split bearing housing, according to the different bearings and shaft requirements, SN2, 5, 3, 6 series, SNL2, SNL5, SD have 2, 5, 3, 6, 3100, 3000, 3200

The bearing housing is divided into: split bearing housing, sliding bearing housing, rolling bearing housing, flanged bearing housing, and outer spherical bearing housing.

Scan the QRcode

Scan the QRcode